Something New - Something Powerful

Copyright George M. Bonnett, JD 2015 All Rights

Reserved

Introduction:

In order to put this in perspective, it is necessary to

start from where we have been. When

solving collisions back in the dark ages, the procedure for using Conservation

of Linear Momentum was the quadrant method.

Being new to accident reconstruction back in the late 70's, and having a

brand new HP-15C calculator and not knowing any better, I managed to program it

to solve Linear Momentum problems using just the two primary formulae for V2

and V1 using the trigonometry functions instead of using the very awkward

quadrant method. In fact, it could

handle four exit fragments for each of the two vehicles in collision.

In early 1986 several years after the formulae had been

given to IAARS, it was on a Radio Shack

PC-2 computer with a small 4 color ink-pen printer and was brought to an AI/AR

training institution to demonstrate to them a new way of doing Momentum

problems. They labeled it

"witchcraft" and unceremoniously told us to leave. For well over 5 years several other

institutions still taught the Quadrant method, even though the initial

institution had finally become a believer.

This method still required knowing all four angles and the departure

speeds immediately out of collision for both vehicles.

Back around 2009-10, while talking with a friend at the PSP

conference in Happy Valley, PA about solving for momentum with less information

using just one vehicle, concern was expressed that the departure angles for

both vehicles were needed to make this work. But what if we only had the CDR

data from one vehicle? There was an

experimental version of REC-TEC, but it required input of both the approach and

departure angles for the two vehicles, in addition to the weight of the second

vehicle. After release a few years ago,

another discussion revealed that my friend was now teaching almost exactly the

same method.

With this methodology integrated into Crush5, in 2015 it

was no longer necessary to input the approach angles as the migration from CDR

data to Crush5 enabled solving for them.

All that is left is solving for the 2 departure angles.

New for 2016 is the integration of Restitution (e) into the

Crush5 solution and the Vectors (EDM-Momentum) module. Knowing the approach angles gives us a Cone

of Departure for the collision. The

REC-TEC Vector module permits 2-variable table integration with Restitution

(e). It is possible that this, coupled

with the implications involving Plane of Impact has brought us ever closer to

finding a viable new solution.

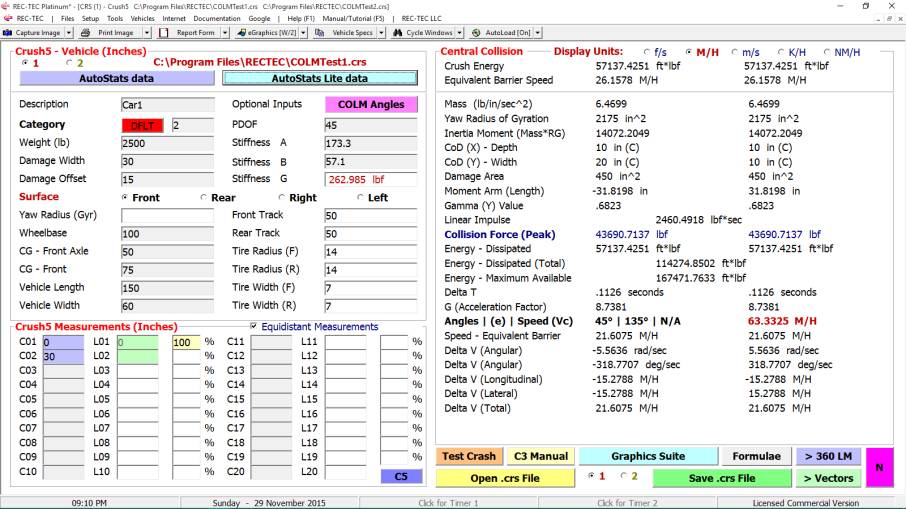

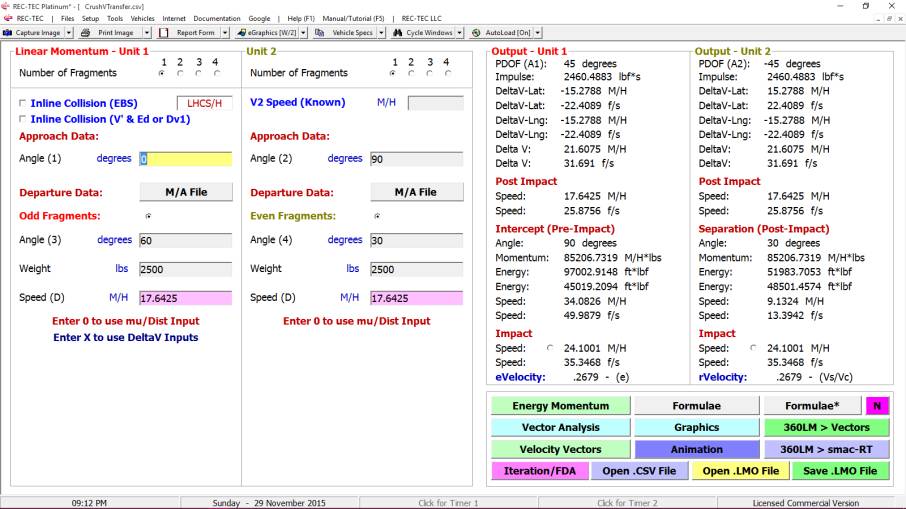

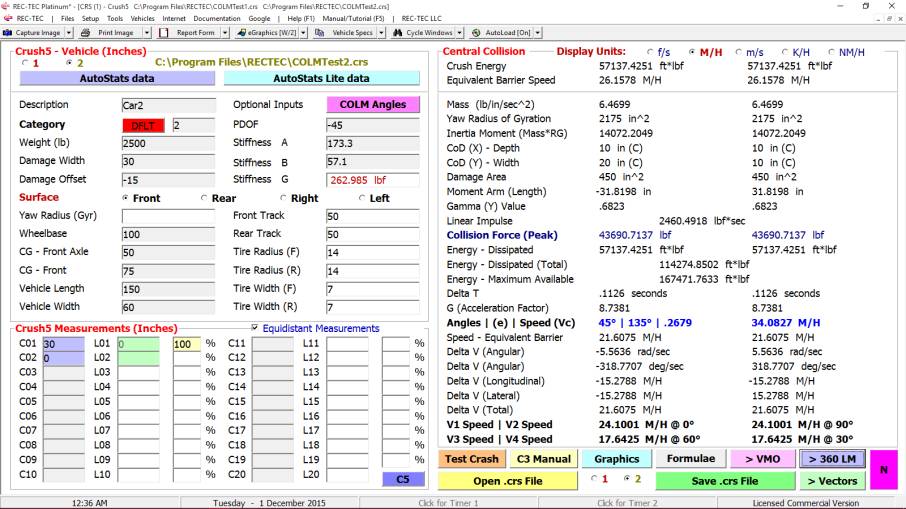

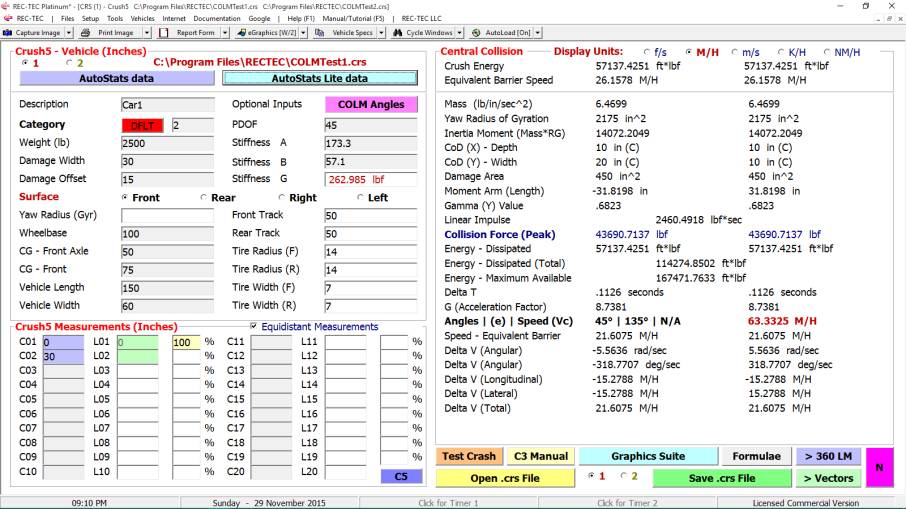

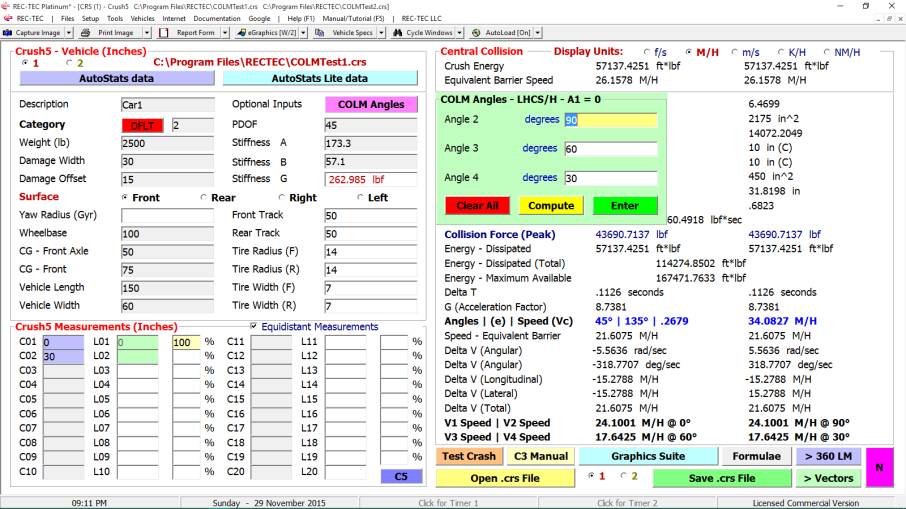

Figure

612-IM42 (2016 Release)

The only noticeable change on this screen is the Angles

| (e) | Speed (Vc) label on the right side of the screen. This has some exciting implications that

will be explored in following screens.

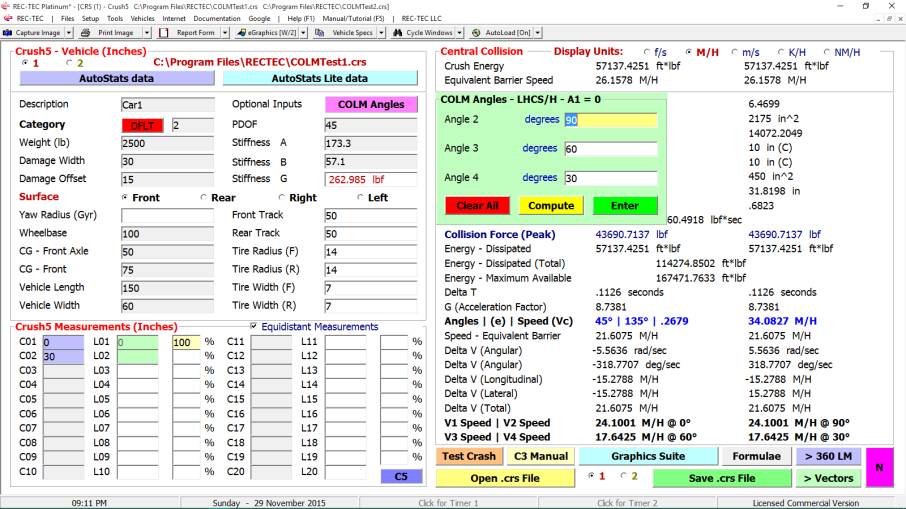

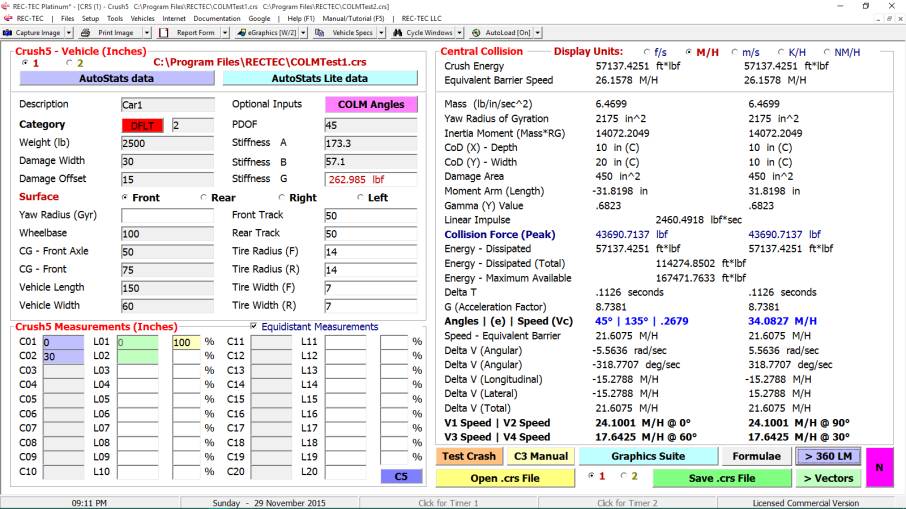

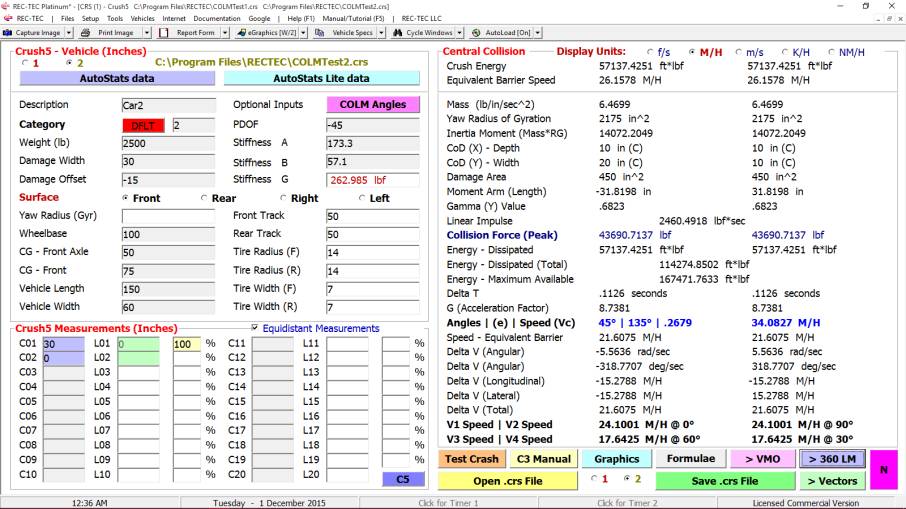

Figure

612-IM43

Clicking on the COLM button displays the COLM

Angles frame that will self-populate based on the PDOF angles (user

override available) of the

vehicles. Angles allow the program to

compute Speeds V1, V2, V3, and V4. REC-TEC can now compute Restitution

(e) based on the angles and speeds.

The reconstructionist is able to use his expertise to form truly

informed opinions from very limited data.

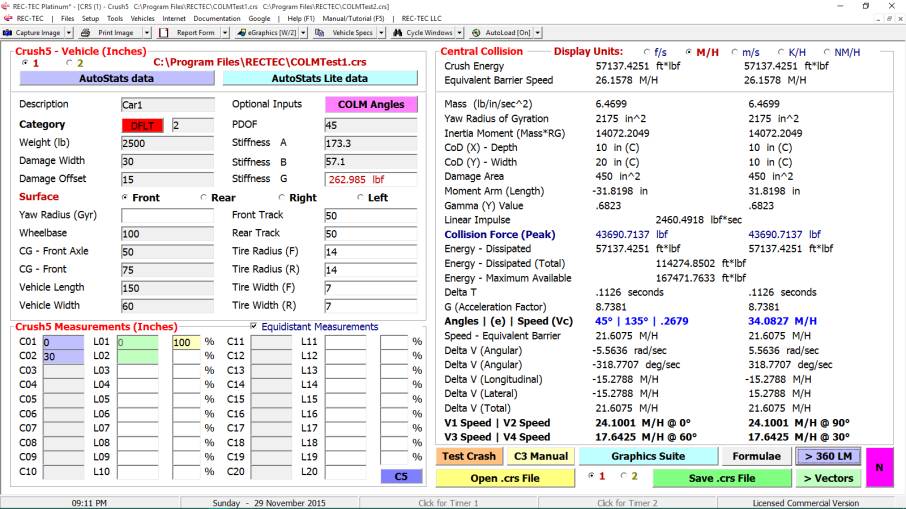

Figure

612-IM44

Figure 612-IM44 displays information on Vehicle 1.

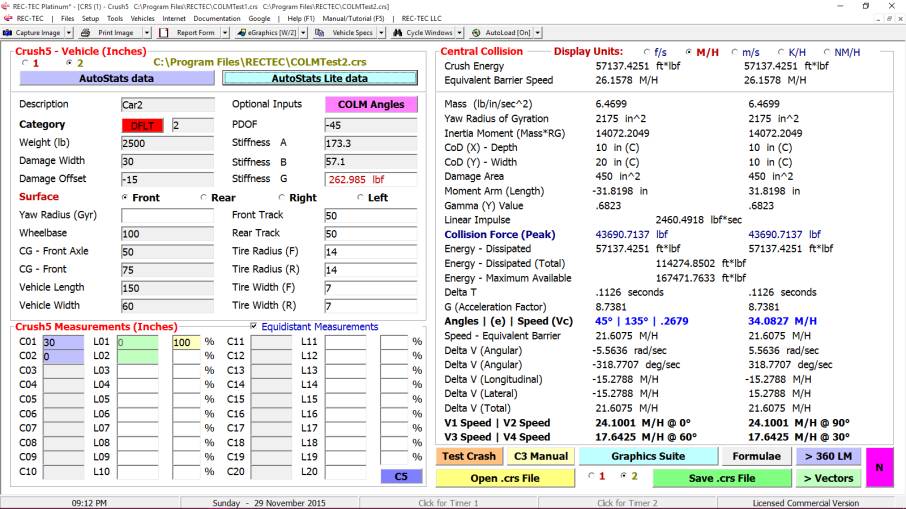

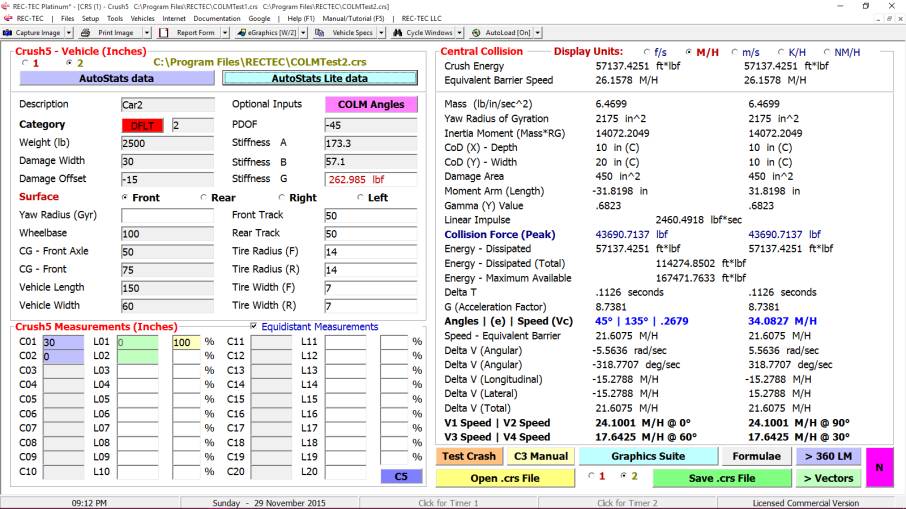

Figure

612-IM45

Figure 612-IM45 displays information on Vehicle 2.

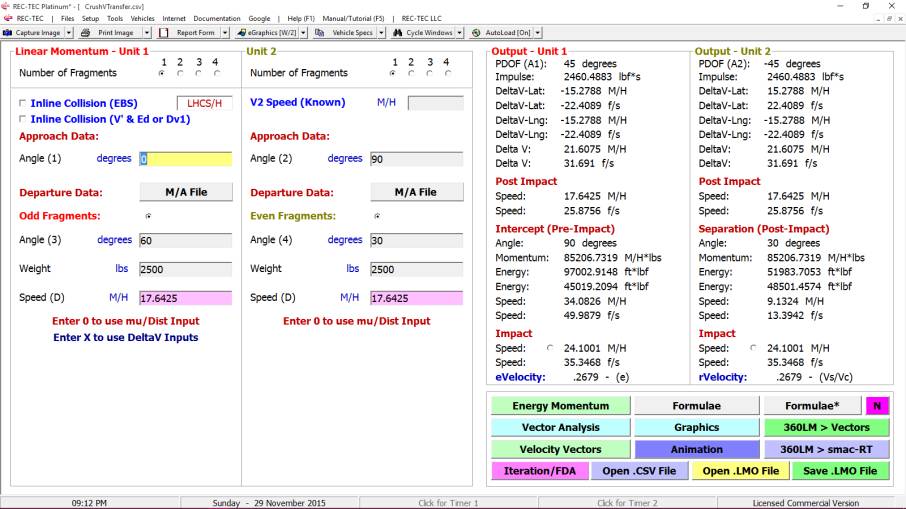

Figure

612-IM46

Figure 612-IM46 displays the information on Vehicle 1 and

Vehicle 2 transferred into 360 LM.

The eVelocity (Restitution) is recalculated in 360 LM

based on the data transferred from Crush5.

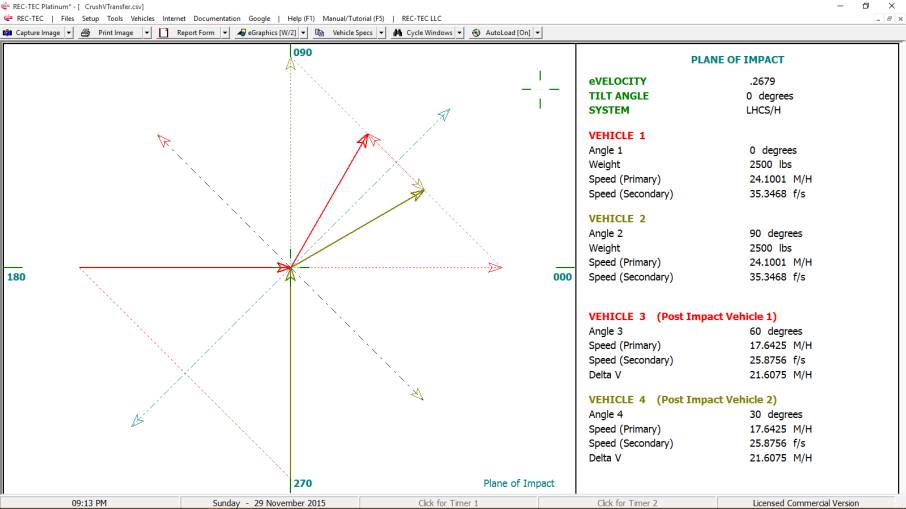

Figure

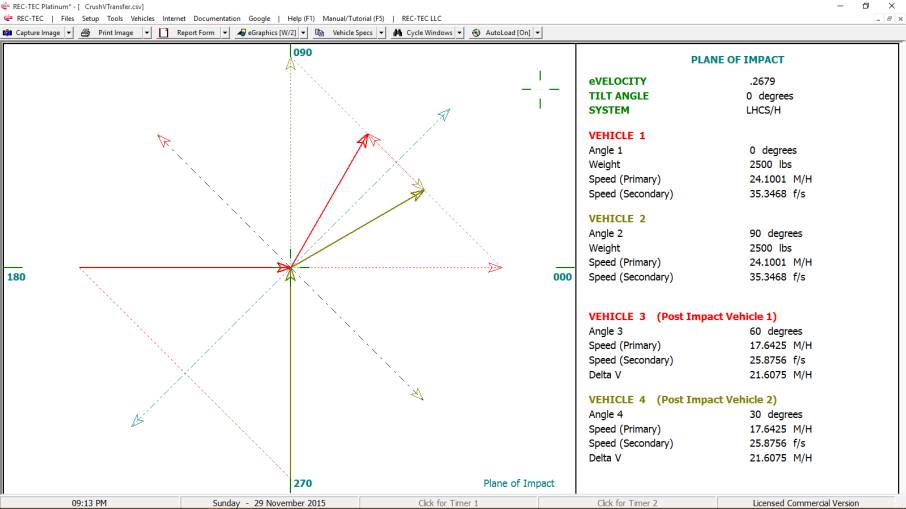

612-IM47

Figure 612-IM47 displays the Plane of Impact basis

for (e).

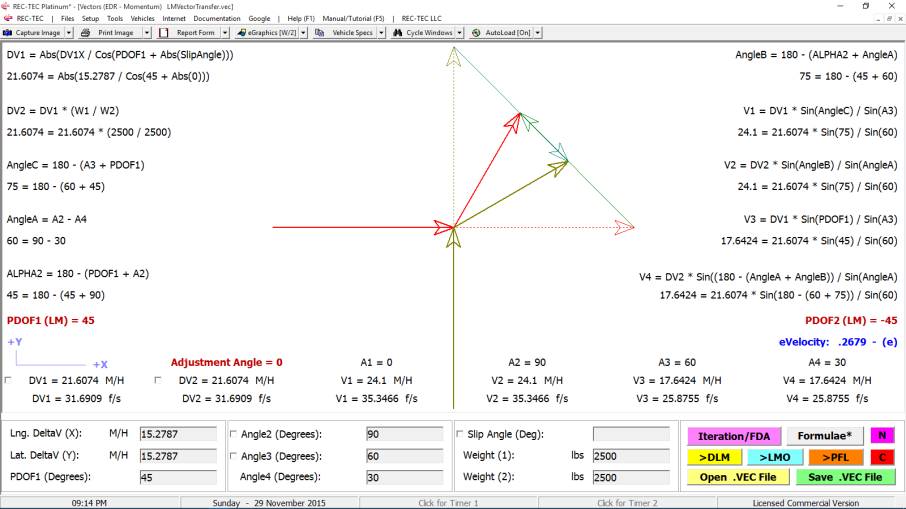

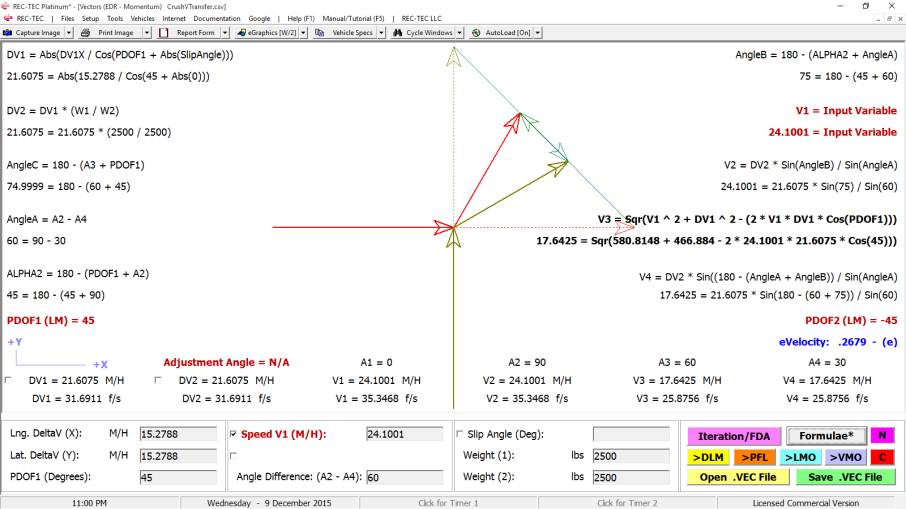

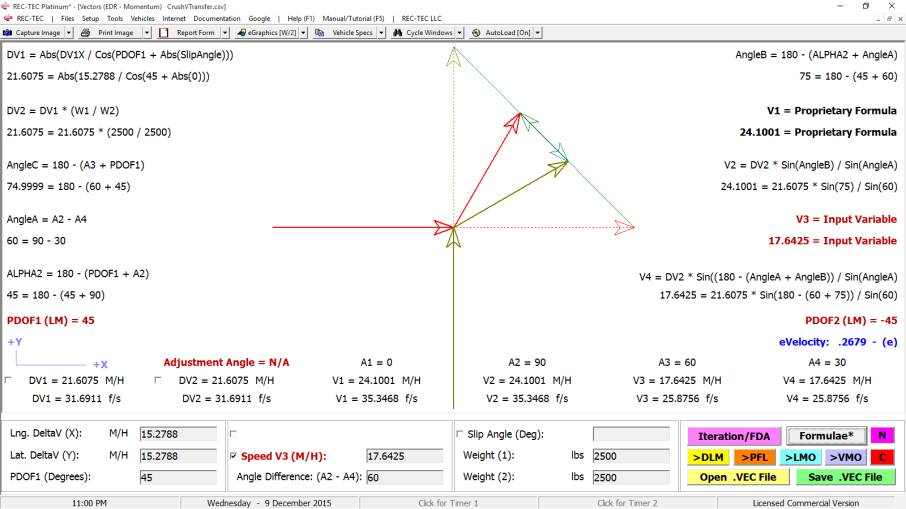

Figure

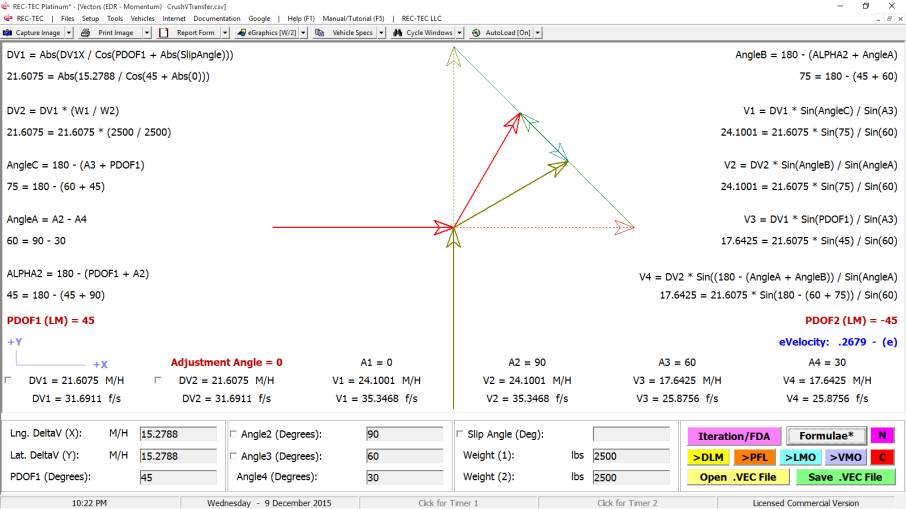

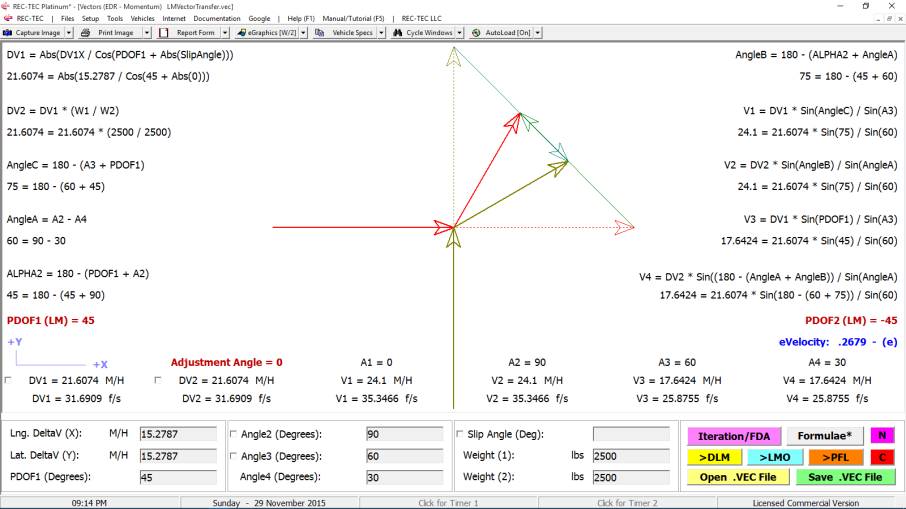

612-IM48

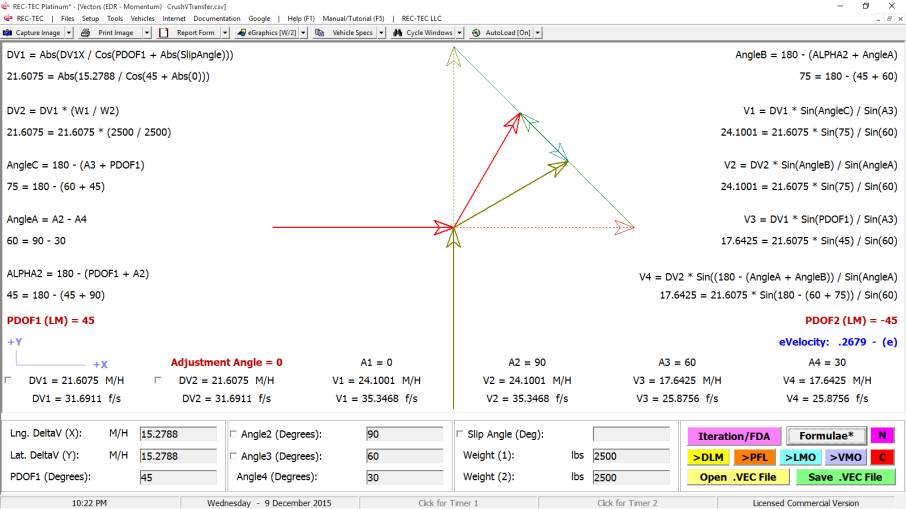

Figure 612-IM48 displays the information from 360 LM

transferred into Vectors (EDR - Momentum), along with a vector diagram

and the formulae used to arrive at the results in this module.

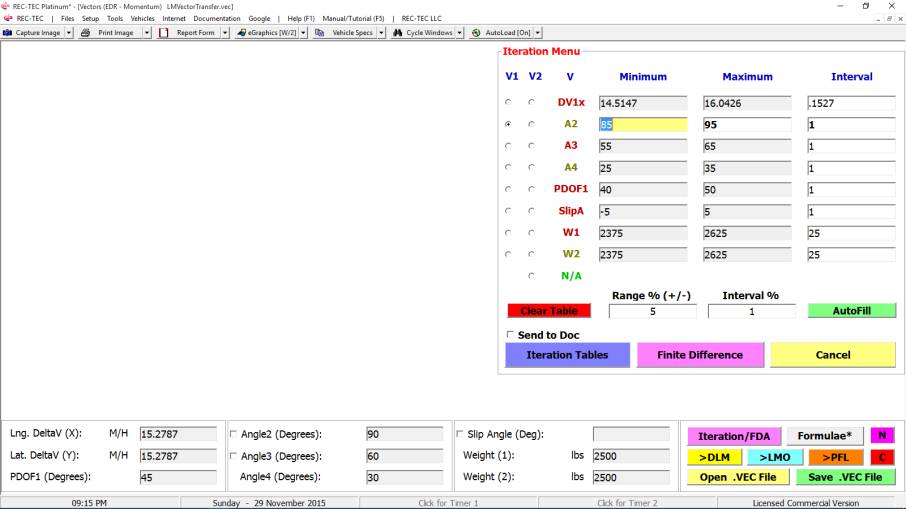

Figure

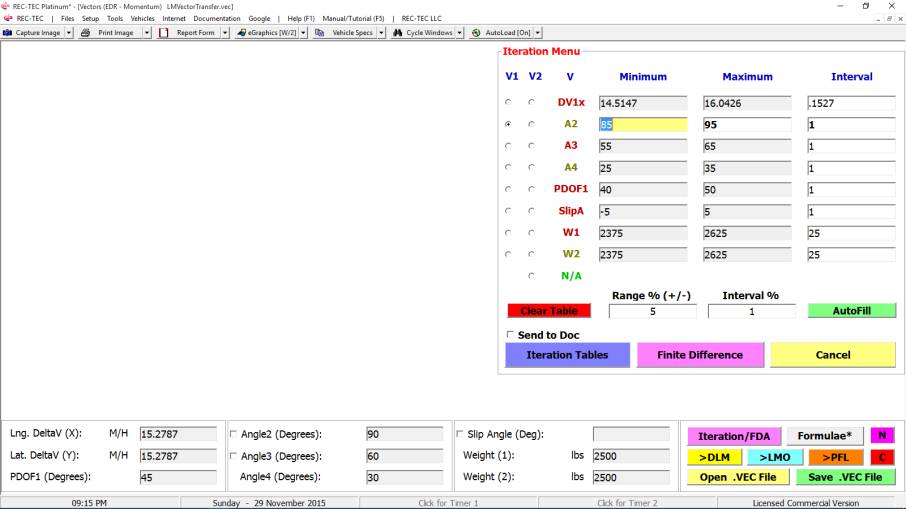

612-IM49

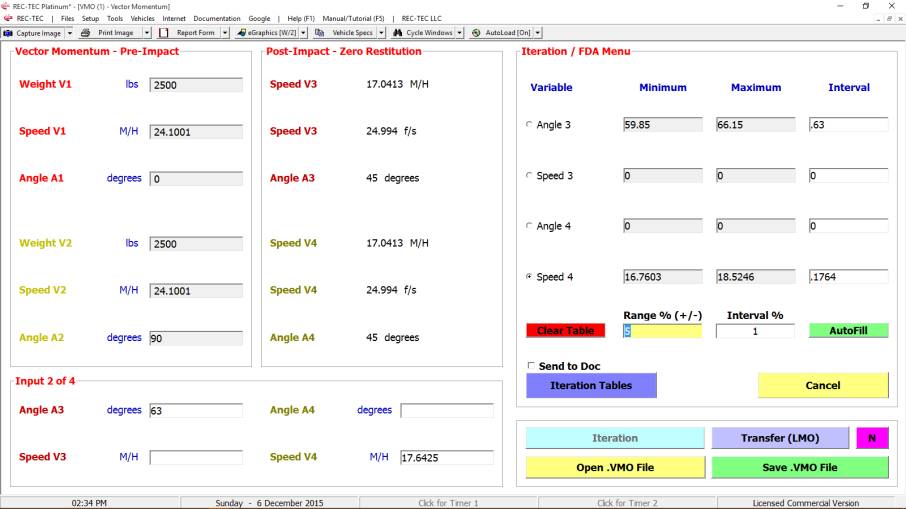

Figure 612-IM49 displays the Iteration / FDA (Finite

Difference Analysis) interface.

Employing the user set Range and Interval, Autofill

has populated the interface with Minimum, Maximum and Interval

information on the associated variables.

These can be overridden by the user.

Note that Iteration in this module can use two variables. Only Angle 2 has been selected here.

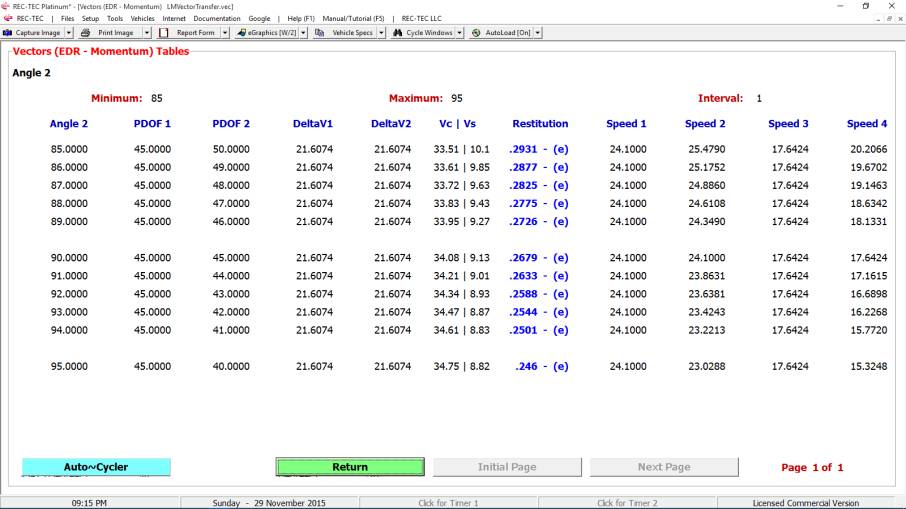

Figure

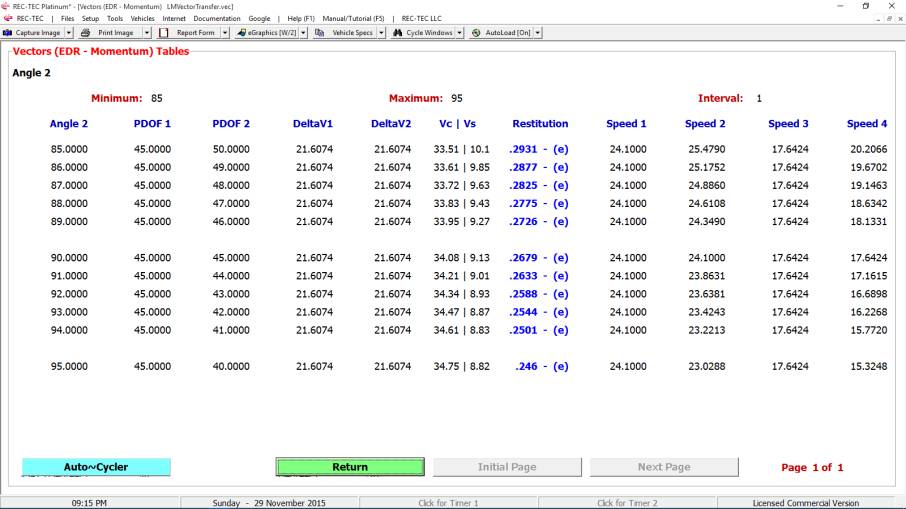

612-IM50

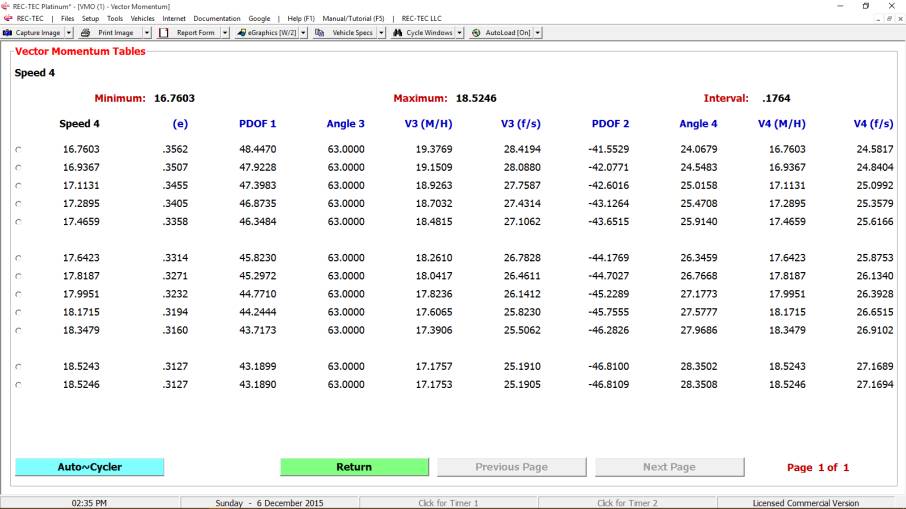

Figure

612-IM50 displays the Iteration screen for Angle 2 based on the

information on the Iteration / FDA interface.

Figure

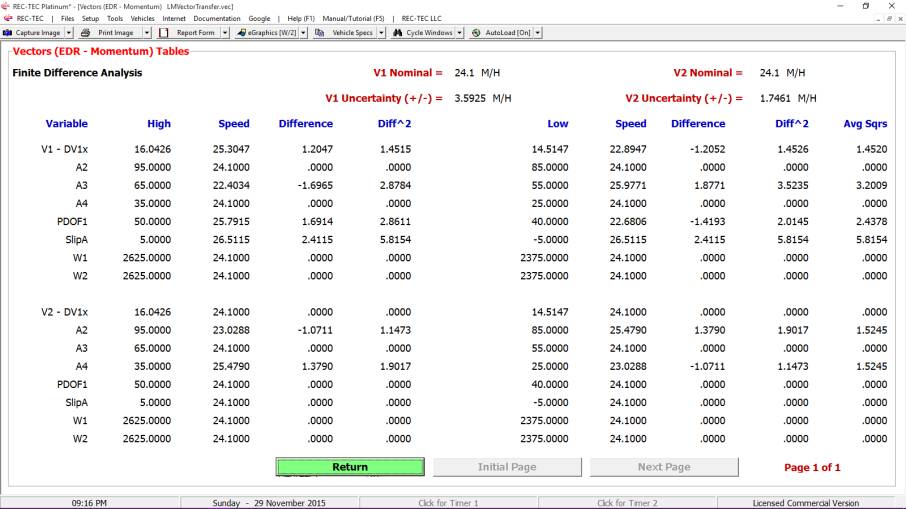

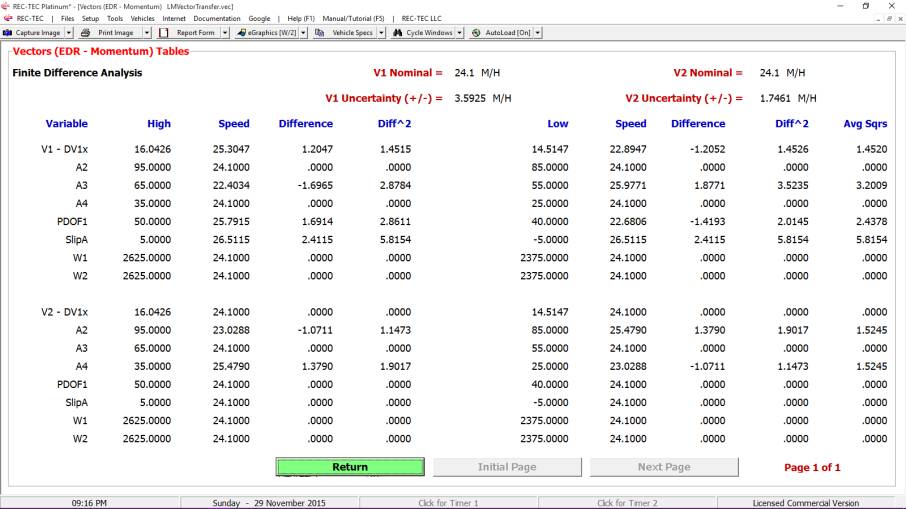

612-IM51

Figure

612-IM51 displays the Finite Difference Analysis screen based on

the information on the Iteration / FDA interface.

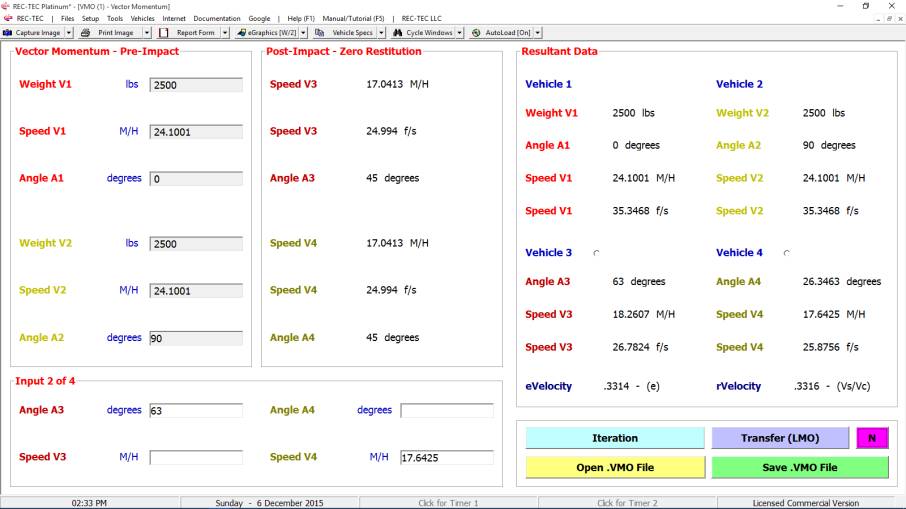

Figure

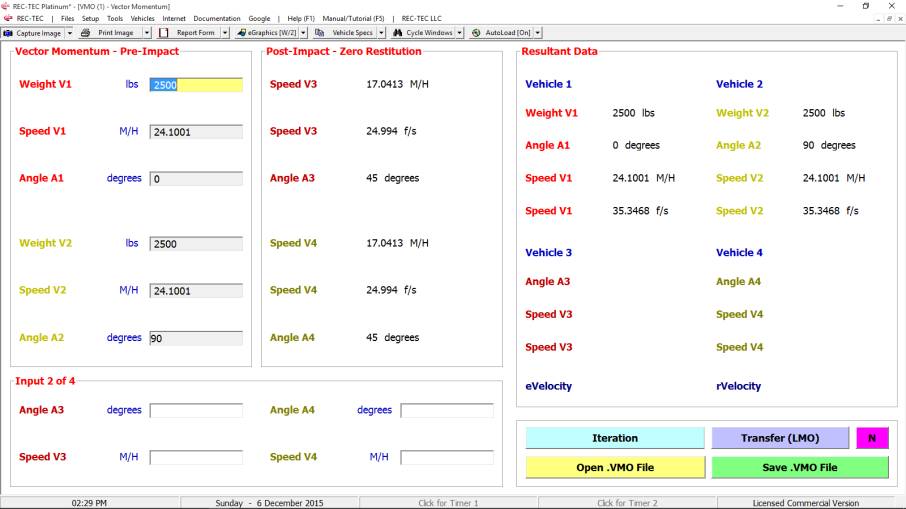

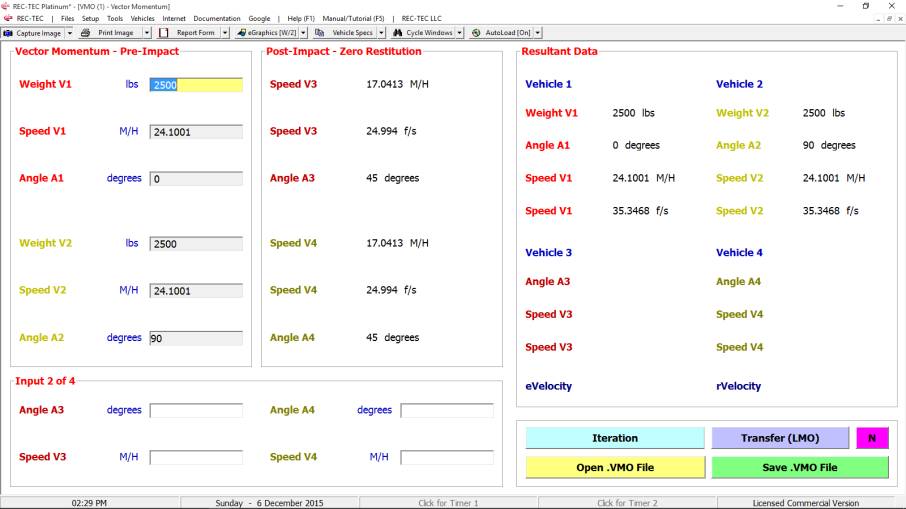

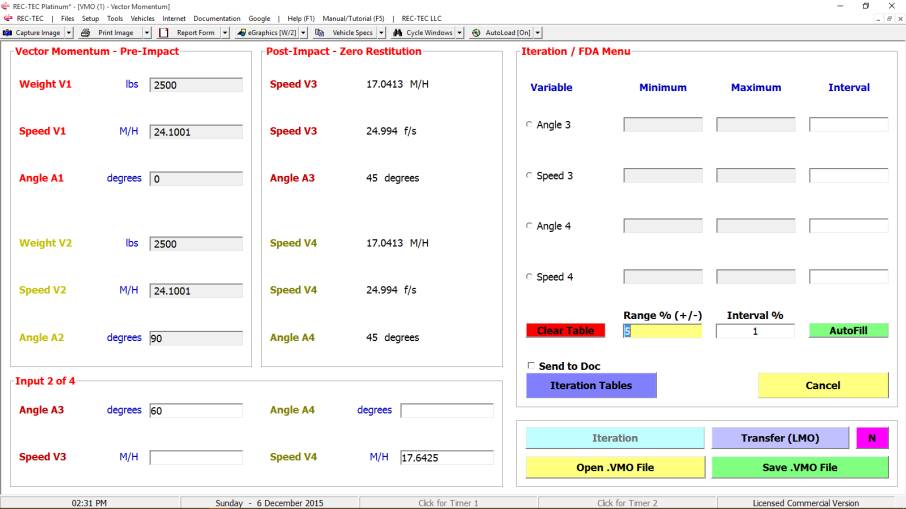

612-IM52

Something New? Yes,

a new pink button [> VMO]. Vector Momentum is like Linear Momentum in

reverse. It calculates post-impact

information. Could this help with

solving for our two departure angles?

It just might - which is why this option has also been added to the Vectors

(EDM-Momentum) module.

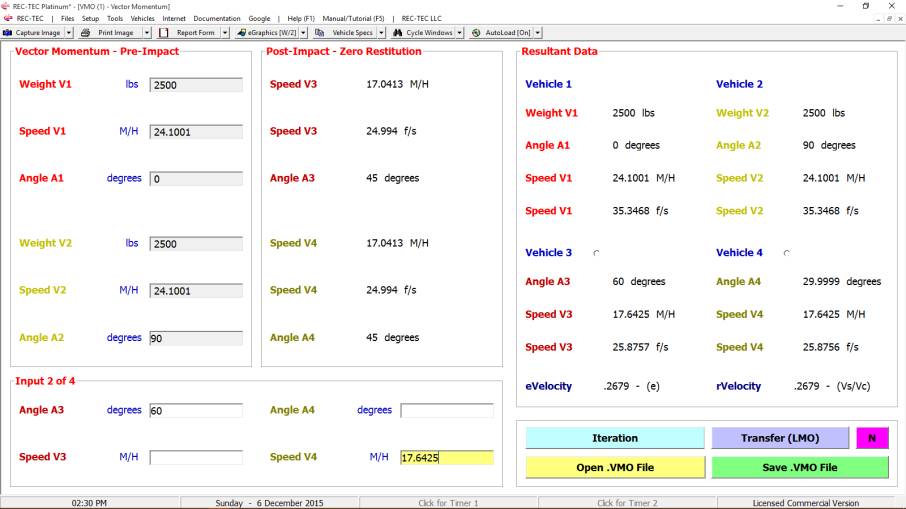

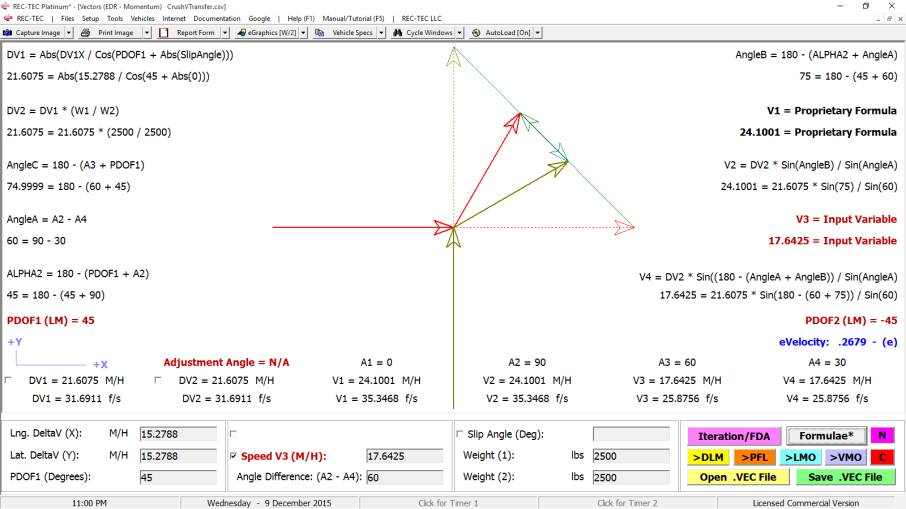

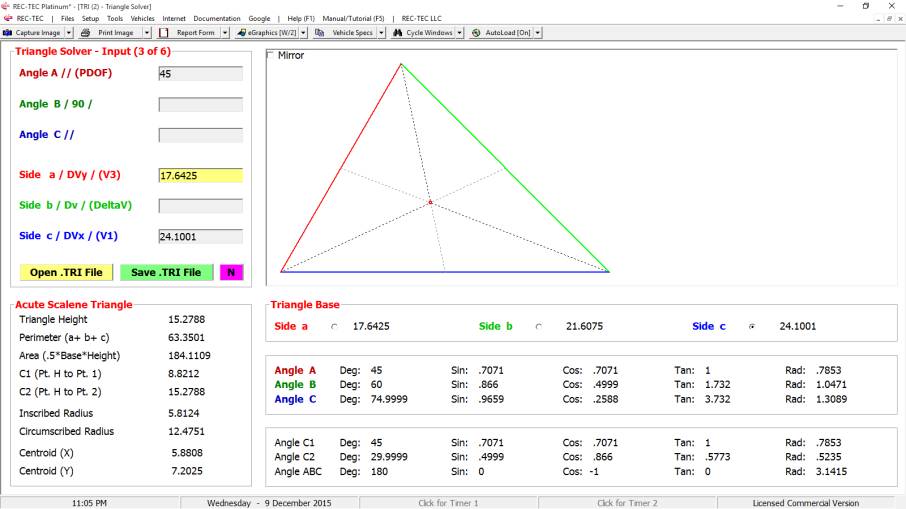

Figure 612-IM53

Well, not exactly, but we do have more options. This module allows us to use either angles,

speeds or a combination of an angle and a speed, and the combination can be on

the same vehicle or different vehicles.

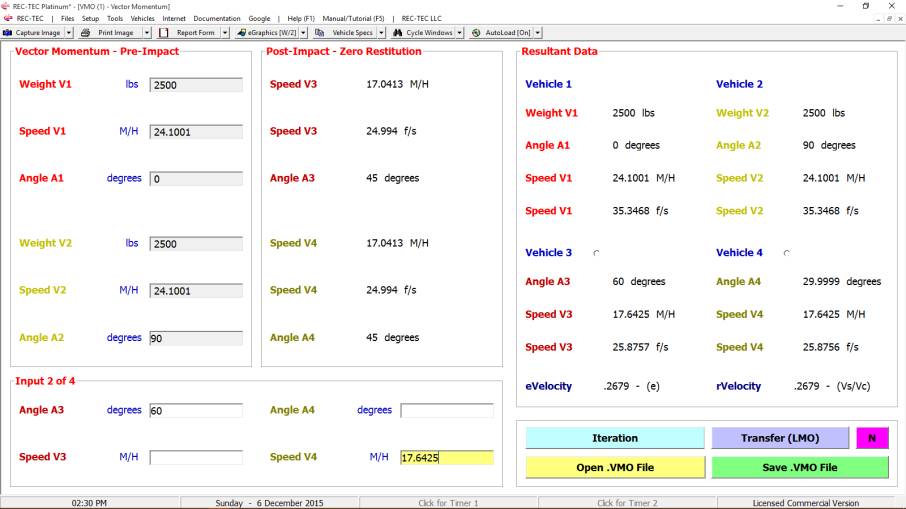

More options just might let us solve the problem. Use 60 degrees for Angle A3 and 17.6425 for

the speed of V4.

Figure 612-IM54

It has calculated A4 to be 29.9999 - remember, the program

truncates at the requested decimal place (1-4). This gives us a lot of flexibility because it gives us more

options. Crush5 (Crash3) gives but one

option, it needs the departure angles.

Vector Momentum permits six (6) different options. More options give more possibilities for

solving the problem, the ultimate goal.

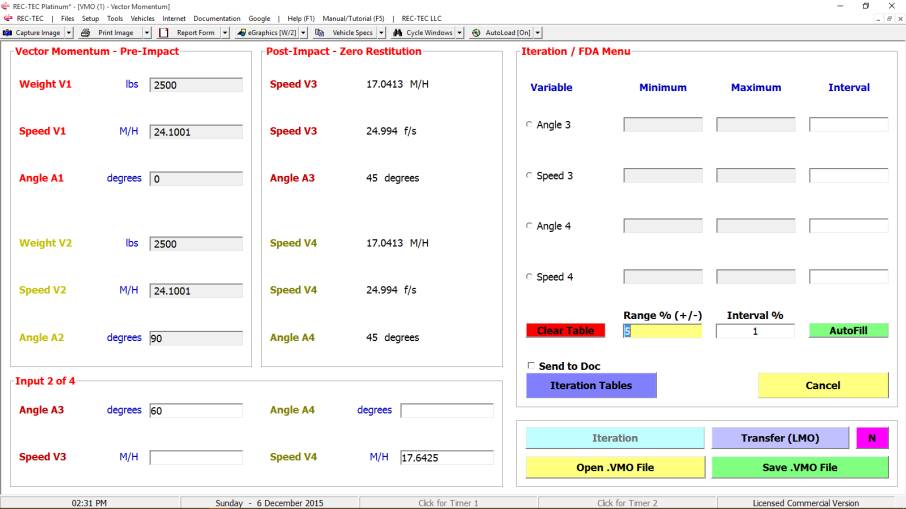

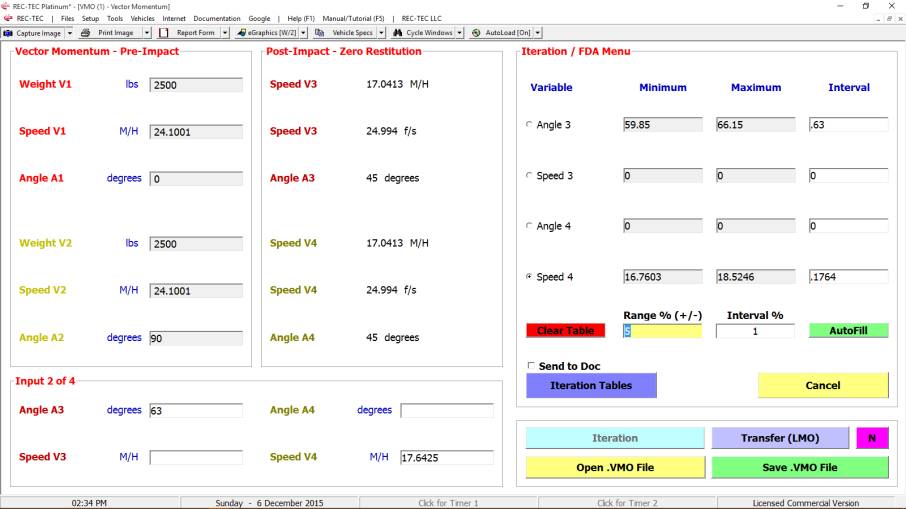

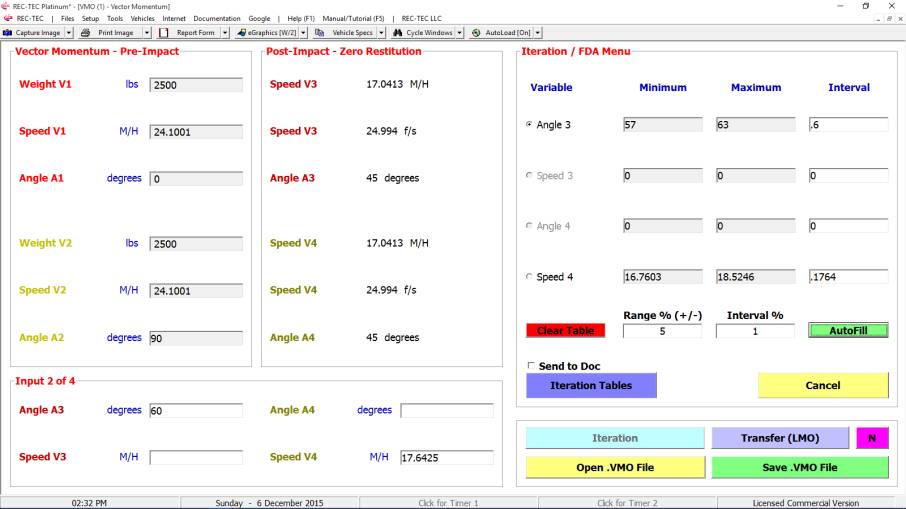

Figure 612-IM55

Enter Range and Interval parameters and then use Autofill

to populate the interface.

Figure 612-IM56

The module only sets the parameters for Minimum, Maximum,

and Interval for the Inputs entered into the Main Interface. While the values can be changed by the user

even for the unavailable variables, they may not be selected for Iteration.

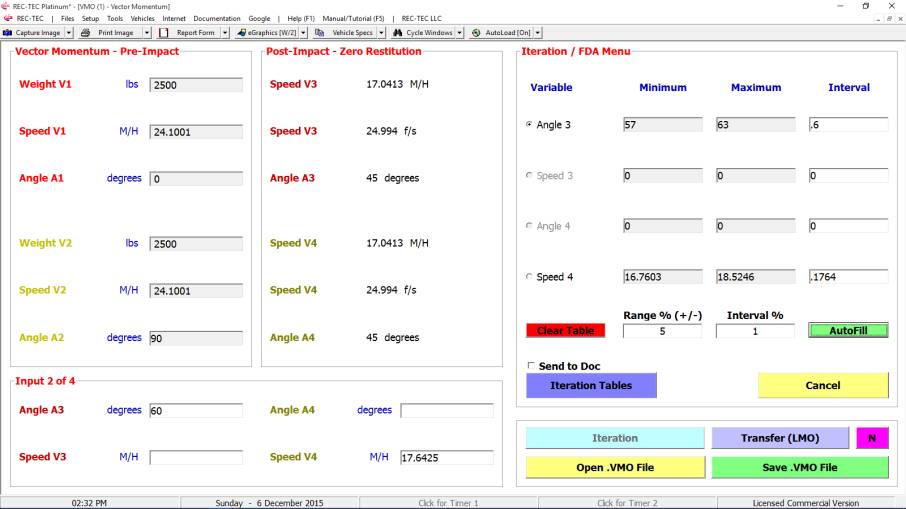

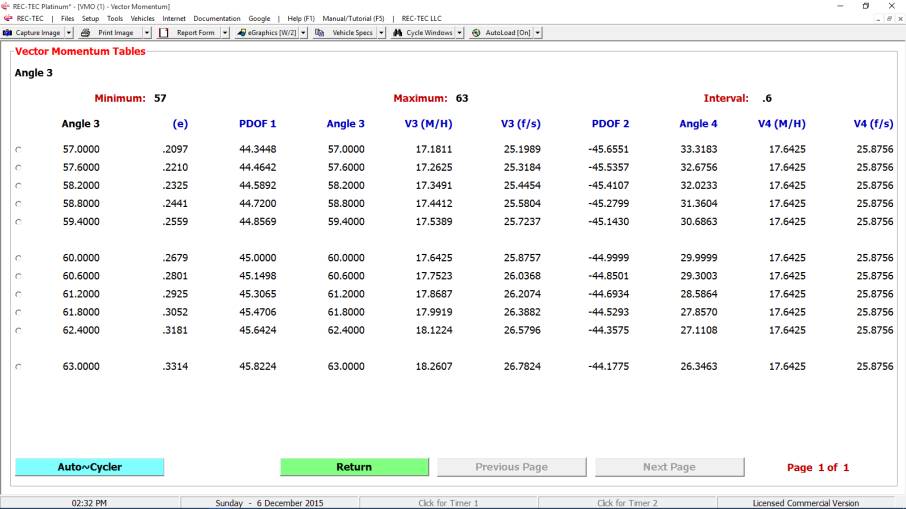

Figure 612-IM57

The radio buttons on the left side of the table allow

Selecting a particular Variable (Angle 3 in this instance) as the default

value. This value will be transferred

to the Main Interface and the Iteration Interface will be reset (AutoFill)

automatically. The 63 degree angle will

be selected to demonstrate this capability.

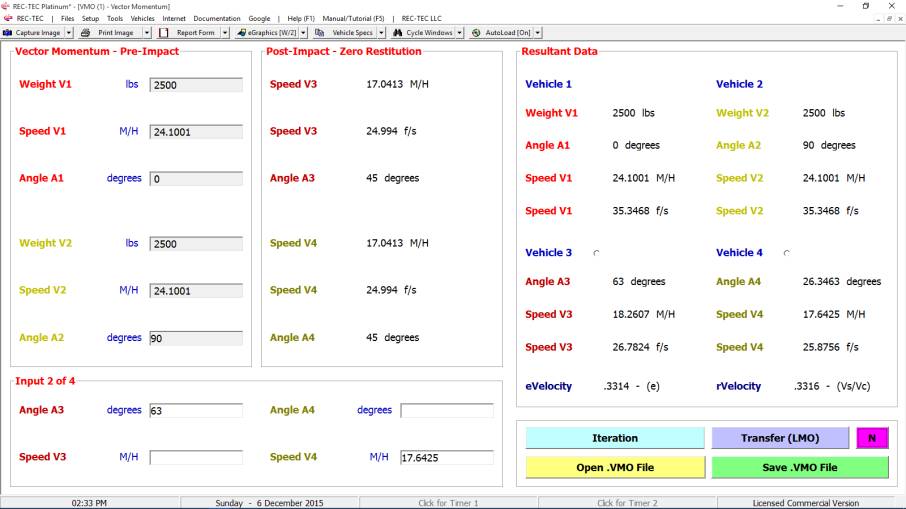

Figure 612-IM58

The transfer was automatic and the program recalculated the

output based on the new value for Angle 3.

Figure 612-IM59

This new Iteration data will be used to generate a new

table for Speed 4.

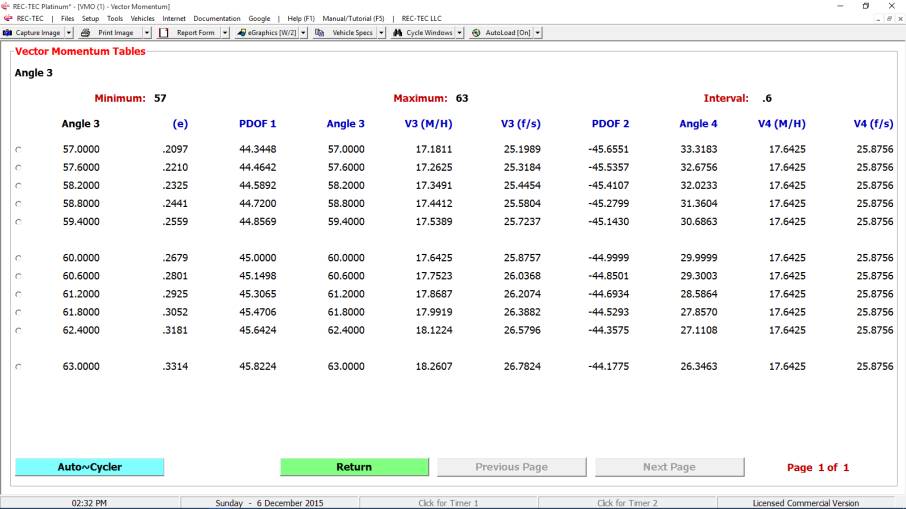

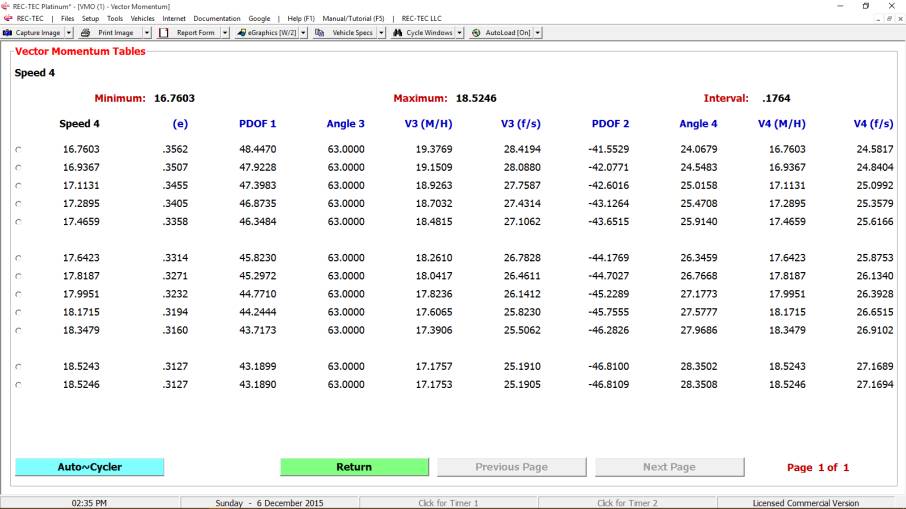

Figure 612-IM60

Shown above the data

for Speed 4 Iteration. Note that the

Restitution and PDOF values for all of these changes are an integral part of

the tables. This gives a fuller picture

of how changing post-impact angles and departure speeds affects the collision.

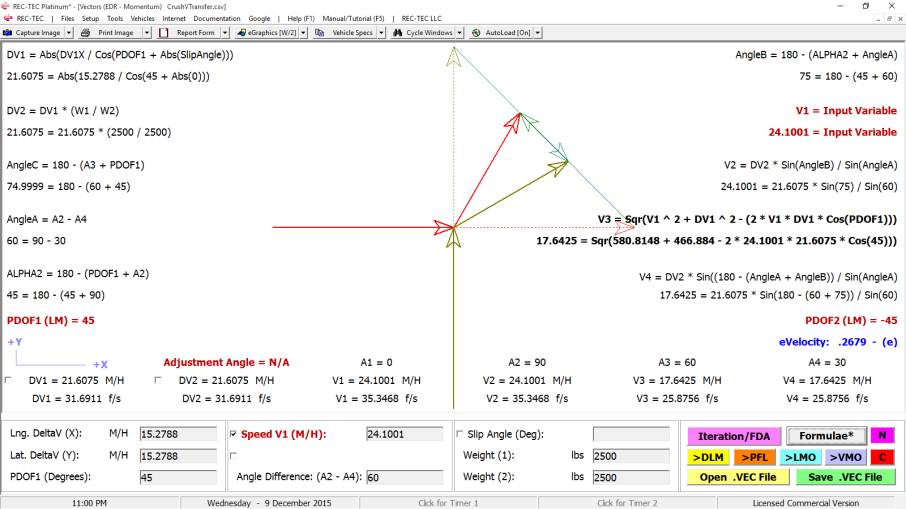

Figure 612-IM61

If reliable data from other sources is available for the

pre-impact or the post-impact speeds of one of the vehicles, approach and

departure angles for that vehicle can be calculated if the angular difference

between the pre and post-impact vehicle is known. Assume we have a V1 of 24.1001 M/H and a V3 of 17.6425 M/H with a

angular difference of 60 degrees between pre and post-impact. Check Angle2 checkbox.

Figure

612-IM62

In this

step we have set the Impact Speed of Vehicle 1.

Figure

612-IM63

Here we

have set the Post-Impact Speed of Vehicle 1 (V3).

Figure

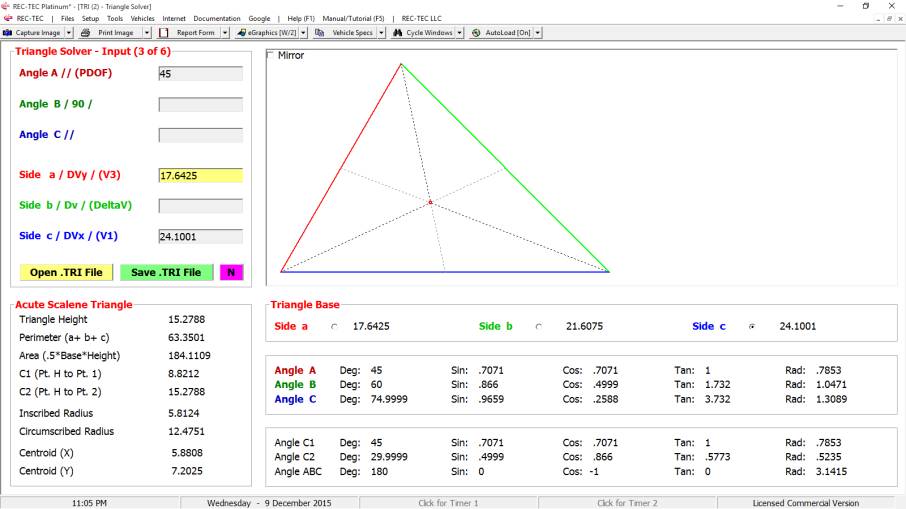

612-IM64

Note: Using correct values for the problem as entered input

values kept the proper relationship for the PDOF, DVx, and DVy values. Use of "override" values will

cause an imbalance that may be unacceptable.

Conclusion:

This paper presents a viable alternative to the CDR only

solution when reconstructing

accidents. REC-TEC

integrating Crush5, 360 Linear Momentum, Vectors (EDR -

Momentum), and Vector Momentum Analysis can combine to produce an

absolutely stunning array of unique attributes specifically designed to assist

in forming your opinions, and reinforcing your informed opinions. If CDR data

on pre-impact and/or post-impact speeds is available, Vectors (EDR -

Momentum), Vector Momentum Analysis, and Triangle Solver can

be used in arriving at a solution.

While the expert is always limited by the data available in

forming opinions, sometimes more data is available than first believed, and

using all of the data in new and different ways can present a new way of

approaching the problem. It has been

the objective herein to provide some outside of the usual box approaches to

collisions where data was at best limited.

SMAC (2D and 3D) from

several companies, "Crash" variants, and several Point-Click-Drag

high-resolution animation packages are available, several costing $10,000

or more for a package that is very limited in scope (and installations). Some

require minimal training of only a few hours with no emphasis on the physics

behind the curtain. All are still

limited to the data available to the reconstructionist, although this

requirement is all too often waived in an effort to let the computer supply the

Suspension of Disbelief for the viewer.

Besides some very fancy (and blatantly overly prejudicial) bells and

whistles that will certainly impress an uneducated trier of fact, exactly what

do these animations (based on simulations that are often based on opinions, or

based purely on opinion) really offer?

They have been lumped together because most of the time they all

accomplish the same thing - a glitzy view of an opinion of one possible

solution that could have happened by a (highly-skilled) expert.

Lest someone think this is an overly harsh critique of SMAC,

Crash variants, and Point-Click-Drag high-resolution animation, REC-TEC

also includes a very efficient SMAC module that is integrated with Crush5

and 360 LM providing a startlingly easy way to set inputs for SMAC

simulation>animation. As recommended by many experts, SMAC et al and CDR

data are excellent secondary, or tertiary tools, when used to verify the

reconstruction. They were never meant to be the primary tool for

"doing" the reconstruction..

In a perfect world, a satellite capable of high-resolution

and high-speed image capture would provide a video of our collision, which

rarely, if ever, happens. REC-TEC

is the next best option.

Question Everything!

Copyright George M. Bonnett, JD 2015 All Rights

Reserved